Resources

Code Report

PRODUCT: Structural Insulated Panels (SIPs)DIVISION: Wood, Plastics and Composites (06)SECTION: Structural Panels (06 12 00) Download Our Code Report Here

ICC-ES Evaluation Report

ICC-ES evaluation report on Foam Laminates’ structural insulated panels: wall and roof panels 8 ft. to 16 ft. long, 6 1/2 in. to 10 1/4 in thick.

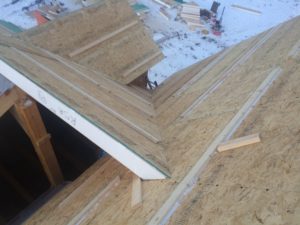

Installation Tips

Read about and download our installation guides for structural and timber frame SIP installation tips.

Home Finishing With SIP’s

Products Foam Laminates of Vermont recommends for covering siding and roofing SIPS.

SIP Installation & Construction

Learn about SIP installation & Construction by Foam Laminates of Vermont.

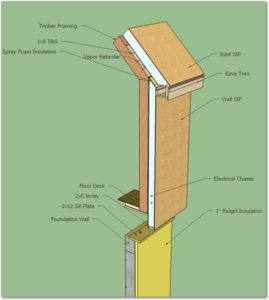

Timber Frame Panel Details

These images show the details of installing timber frame panels on different parts of a structure.

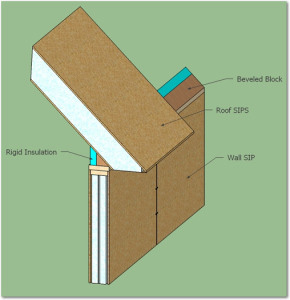

Structural Insulated Panel Details

These images show the details of installing structural insulated panels on different parts of a structure.

FAQs

About SIPs

What are SIPs?

Structural insulated panels (SIPs) are high performance building panels used in floors, walls, and roofs for residential and light commercial buildings. The panels are made by sandwiching a core of rigid foam plastic insulation between two structural facings, such as oriented strand board (OSB). Other skin materials can be used for specific purposes. SIPs are manufactured under factory controlled conditions and can be custom designed for each home. The result is a building system that is extremely strong, energy efficient and cost effective. Building with SIPs will save you time, money and labor.

How much do SIPs weigh?

Our standard EPS wall SIPs weigh about 3.25 lbs per square inch, so a 8′ x 4′ 6.5 inch thick EPS wall sip would weigh about 104 pounds. Our Neopor SIPS weigh slightly more at 3.5 lbs per square inch, so an 8′ x 4′ wall sip would weigh about 112 pounds.

How much do SIPs cost?

Contact us. However, the material price does not reflect the labor savings capable with SIP construction.

A study conducted by the R.S. Means shows that building with SIPs can reduce framing labor by as much as 55 percent over conventional wood framing. Builders can also expect decreased jobsite waste disposal costs and savings on HVAC equipment. When all these factors are considered, building with SIPs is often less expensive than other building systems.

How strong are SIPs?

The structural characteristics of SIPs are similar to that of a steel I-beam. The OSB skins act as the flange of the I-beam, while the rigid foam core provides the web. This design gives SIPs an advantage when handling in-plane compressive loads.

SIPs can be engineered for most applications. Detailed information on the structural performance of SIPs is available from SIPA member manufacturers.

How green are SIPs?

Structural insulated panels are one of the most environmentally responsible building systems available. A SIP building envelope provides continuous insulation, is extremely airtight, allows for better control over indoor air quality, reduces construction waste, and helps save natural resources. Life cycle analysis has shown that SIP homes have a tremendous positive environmental impact by reducing energy use and greenhouse gas emissions throughout the home’s life cycle.

How much money can I save with SIPs?

Builders can save money through decreased construction and labor costs. A high performance building envelope often allows HVAC equipment to be downsized and ductwork to be minimized. Builders can also significantly reduce jobsite waste disposal and temporary heat during construction. Homeowners that incorporate other energy-efficient features into a SIP home can see utility savings of 50 percent or more.

How much faster can I build with SIPs?

SIP homes go up much faster than traditionally framed buildings. A properly trained SIP installation crew can cut framing time by 55 percent compared to conventional wood framing, according to a third-party study conducted by R.S. Means. Panels are manufactured as big as 8- by 24-ft., so entire wall and roof sections can be put up quickly, reducing dry-in time. SIPs are ready to install when they arrive at the job site, eliminating the time needed to perform the individual job site operations of framing, insulating and sheathing stick-framed walls. Electrical chases are typically provided in the core of panels, so there is no need to drill through studs for wiring.

I want to build a SIP home. What is the first step?

For homeowners, the first step is to identify a quality builder who has experience with SIP construction. An experienced SIP builder will manage the plan conversion and review process.

For a builder looking to start their first SIP project, the first steps are to find a manufacturer or dealer/distributor to work with and explore some of the many educational resources available.

SIP Installation and Construction

How does the SIP design and fabrication process work?

The construction of a SIP home or commercial building begins with the construction documents. Once the construction documents are in the hands of a SIP manufacturer, dealer/distributor, or design professional, they are converted to SIP shop drawings that give the dimensions of each individual panel.

The shop drawings are reviewed by the builder, engineer, the building owner, and other involved parties. Once the shop drawings are finalized, the SIPs are fabricated and shipped to the jobsite for installation.

What considerations do you need to take into account when building with SIPs vs. conventional framing?

The majority of construction with SIPs is very similar to conventional framing. SIPs accept dimensional lumber and are fastened together using staples, nails or screws. Proper sealing is very important when assembling SIPs. All joints need to be sealed with specially designed SIP sealing mastic or expanding foam sealant, and in some cases self-adhesive SIP tape. SIPs also require consideration of how panels will be staged and placed on the jobsite. Although smaller 8- by 4-ft. panels can be set by hand, larger 8- by 24-ft. panels require the use of equipment to unload and set.

How are SIPs supported? Are there studs in the panels?

For most applications, SIPs are structurally self-sufficient. The structural characteristics of SIPs are similar to that of a steel I-Beam. The OSB skins act as the flange of the I-beam, while the rigid foam core provides the web. This design is extremely strong and eliminates the need for additional framing.

In cases where a point load from a beam or header requires additional support, a double dimensional lumber spline or engineered wood spline is field installed at in-plane panel connections.

SIPs are also used as curtain walls for steel frame or timber frame structures. In large commercial applications SIPs can minimize the amount of structural support needed and reduce material costs.

In roof applications, SIPs rely on beams and purlins for support. SIPs can span long distances, allowing a minimal amount of structural supports to be used.

What is the R-value of SIPs?

R-values for SIPs depend on the thickness of the SIP and the type of core material that is used. See SIPA’s R-value chart for the minimum R-values of commonly available SIPs.

Static R-values, like those included in the chart, rate the effectiveness of insulating material. However, they do not accurately describe how products perform in a real world setting. When fiberglass or other types of insulation are installed, they are installed around structural members made of wood or metal that have very poor insulating value. Field-installed insulation materials are also prone to installation imperfections.

The Department of Energy’s Oak Ridge National Laboratory has studied and tested the performance of entire wall assemblies in large sections. The resulting whole-wall R-value data reveals that a 4-inch SIP wall rated at R-14 outperformed a 2×6 wall with R-19 fiberglass insulation.

Why does R-Value increase when temperature decreases?

The R-value of all materials – insulation or not – changes when the mean temperature to which they are exposed changes. Temperature is a measure of the velocity of the atoms or molecules in a given material. Higher temperatures mean a higher molecular velocity (in a solid this would be in the form of more rapid vibrations). Higher temperatures and the corresponding higher velocities (vibrations) transmit heat energy through the material more rapidly, resulting in a lower R-value. Conversely, lower temperatures and correspondingly lower velocities result in higher R-values.

How are electrical wiring and fixtures installed?

Electrical wires are pulled through precut channels inside the core of the panels called “chases.” Chases are added during the manufacturing process according to the electrical design of the home. Electricians can feed wires through panel chases without compressing the insulation or drilling through studs.

What is shingle ridging? Does shingle ridging occur in SIP buildings?

Shingle ridging is a bulging of asphalt roofing material that occurs along the joints of engineered wood panels used in roof applications. This rare phenomenon is caused by changing moisture content in the roof sheathing and occurs in traditional truss-framed roof assemblies as well as SIP roof assemblies.

The ridges caused by the expansion of SIP roof panels may be an aesthetic blemish, but it does not affect the performance of the roofing or the SIP roof panels.

Several assemblies that prevent shingle ridging are described in the Builder’s Guide to Structural Insulated Panels (SIPs). Specifying a cold roof, or simply over-sheathing the roof with an additional layer of OSB staggered over the panel joints, will eliminate the possibility of shingle ridging. Alternately, wood shingles, wood shakes, or a standing seam metal roof can be used in place of asphalt shingles.

How do SIPs react to Fire?

Like all wood frame buildings, SIPs present a manageable fire risk when their construction meets the fire precautions listed in the building code. Residential codes typically require the application of a 15-minute fire-resistant thermal barrier on the interior for all residential structures, accomplished by applying 1/2-in. thick gypsum board or a material of equivalent thermal performance.

Light commercial or multi-use buildings of Type V Fire Rated construction often require a one-hour fire rating and/or sprinkler systems. Many SIP manufacturers can provide tested assemblies for both walls and roofs that meet the one-hour fire resistance tests outlined in ASTM E 119. Check with your local manufacturer for specific assemblies.

Can SIPs be modified on-site?

On-site modification can easily be done using a few additional SIP specific tools. Thick panels can be cut using a beam saw or a beam cutting attachment to a circular saw. The foam core can then be recessed for splines or dimensional lumber using a hot wire foam scoop or specialized angle grinder attachment.

Do SIPs block sound transmission?

The sound resistance of a SIP wall depends on the thickness of the gypsum drywall applied, the exterior finish applied and the thickness of the insulating foam core that is used. SIPs are especially effective at blocking high frequency noise and most homeowners notice the quiet comfort of a SIP home. However, low frequency sounds are not as effectively stopped by a SIP building envelope.

For multifamily and commercial buildings, a universal sound transmission coefficient (STC) is used to specify the sound resistance of wall assemblies. Assemblies with a range of STC ratings are available, including options with a STC rating greater than 50 for party walls in multifamily buildings. SIP manufacturers can provide more information on these assemblies.

Are SIPs compatible with other building systems?

SIPs are compatible with almost any building system. Wall panels can sit on a variety of foundation materials, including poured concrete, blocks, or insulated concrete forms. SIPs are sized to accept dimensional lumber and are seamlessly compatible with stick framing. Builders may choose to build with SIP walls and a conventional truss roof, or stick walls and a SIP roof with little difficulty. SIPs are also popular as a method of providing a well-insulated building enclosure for timber frame structures.

Are SIPs accepted by building codes?

SIP construction is recognized by the International Code Council body of building codes, which are used by most jurisdictions in the U.S.

For residential buildings, specific construction practices for SIP wall systems are included in Section R614 of the 2009 International Residential Code. For applications beyond the scope of Section R614, the building inspector will typically require a licensed engineer or architect to approve the building plans prior to construction. An engineer’s approval is always required in high wind areas, high seismic zones and commercial buildings.

Builders can contact a licensed design professional by searching SIPA’s Membership Directory.

Home Finishing with SIPs

Can recessed lights be used in SIPs?

Recessed lights should never be embedded in structural insulated panels. To install recessed lights, an interior soffit must be constructed.

Can kitchen cabinets be attached to SIPs?

It is recommended that the cabinet manufacturer provide instructions on how to attach their product to SIPs. Typically, an increased fastener schedule is required. Another option is to install plywood strips behind the cabinets to provide additional holding strength for fasteners.

If the cabinet manufacturer does not offer recommendations for attaching their product to SIPs, a licensed architect or engineer can calculate the appropriate fastener frequency by obtaining fastener pullout capacities from a SIP manufacturer.

Can plumbing be installed in SIPs?

Plumbing should not be located in exterior SIP walls because of the possibility of condensation or supply lines freezing in cold climates. During the design phase of the project, all plumbing should be relocated to interior walls.

If plumbing must be located on an exterior wall, it is recommended that a surface chase be installed on the interior of the wall to conceal plumbing. Another option is to construct a small section of the wall using conventional wood framing that can be used to run plumbing. Plumbing penetrations such as DWV can be placed through SIPs if they are thoroughly sealed to prevent air infiltration.

How do I attach siding or other exterior claddings to SIPs?

Builders should consult the siding manufacturer’s installation instructions for how to attach their product to SIPs. Because SIPs use very little solid lumber, an increased fastening schedule is often required when attaching exterior cladding.

If the siding manufacturer does not offer recommendations for attaching their product to SIPs, a licensed architect or engineer can calculate the appropriate fastener frequency by obtaining fastener pullout capacities from the SIP manufacturer.

It is also important that proper moisture management procedures be followed when applying any type of cladding to SIPs. The Builder’s Guide to Structural Insulated Panels (SIPs) provides details for attaching various types of cladding materials. With the exception of metal and vinyl siding, the Builder’s Guide recommends that all claddings be installed with a drainage gap between the cladding and the weather resistant barrier in climates that average more than 20 inches of annual rainfall.

Ventilation

How important is ventilation?

SIP buildings are extremely airtight and require mechanical ventilation. Ventilation systems bring fresh air into the building in controlled amounts and exhaust moisture-laden and stale air to the outside. By limiting air exchange to controlled ventilation systems, SIP homes allow for all incoming air to be filtered for allergens and dehumidified, creating better indoor air quality. Proper ventilation is important in all homes to preserve indoor air quality.

How do I properly size HVAC equipment?

A high-performance SIP building enclosure often allows smaller HVAC equipment to be specified. It is important to work with a qualified HVAC professional that can accurately estimate the low levels of air infiltration in a SIP home or commercial building. Proper HVAC sizing is crucial because an oversized HVAC system will fail to reach the steady operating rate the equipment was designed for. Short cycling HVAC equipment will be less energy efficient and require more maintenance than properly sized HVAC equipment.

Does a building with a SIP roof need to be ventilated?

The area inside a SIP building envelope is considered conditioned space and will be ventilated by the building’s HVAC system. There is no need to provide a vented attic beneath a SIP roof, and doing so would compromise the conditioned space of the building.

Research conducted by Building Science Corporation on test homes in hot climates demonstrates that including the attic in the conditioned space allowed for more energy-efficient space conditioning and less probability of moisture related issues. [Rudd, Armin and Joseph Lstiburek. Vented and Sealed Attics in Hot Climates. Building Science Press, 1998]

Some building science experts recommend venting the roof by providing an air space between the SIP roof panels and the roofing material (known as a “cold roof”). This practice is not a requirement for SIP buildings, but an extra measure to improve the durability and moisture resistance of the building.

Are vapor barriers required in SIP buildings?

Air barriers or vapor barriers are not required in SIP buildings because properly sealed SIPs create a code-compliant air barrier with a permeability rating of less than 1.0 perm. In addition, the foam core of SIPs is solid and continuous throughout the wall, eliminating the convection and condensation issues that can occur in cavity walls.

How do SIPs improve indoor air quality?

The airtightness of the SIP building envelope prevents air from gaining access to the interior of the home except in controlled amounts. A controlled indoor environment is both healthy and comfortable. Humidity can be controlled more easily in a SIP home, resulting in a home that is more comfortable for occupants and less prone to mold growth and dust mites.

Warranty/Susceptibility

Do roofing manufacturers warranty asphalt shingles over SIP roofs?

Some roofing manufacturers warranty asphalt shingles over unvented SIP roofs, while others void their warranty because of higher shingle temperatures. Research conducted by Building Science Corporation reveals that although asphalt shingle temperatures increase slightly (2 – 3 degrees F) in an unvented roof assembly, the color of the shingles and the roof orientation have a much more profound impact on the durability of shingles. According to the Builder’s Guide to Structural Insulated Panels (SIPs) published by Building Science Corporation, the typical reduction of shingle life over an unvented SIP roof assembly is between one and two years.

Builders seeking to comply with roofing manufacturer warranties can choose from a variety of more durable, non-asphalt roofing materials or provide a venting space between the SIP roof panels and the roofing material (known as a cold roof).

Can SIPs be replaced or repaired if damaged?

If panels are damaged, a structural engineer needs to assess the damage to determine what is cosmetic and what is structural. If the damage is only cosmetic, then the source of moisture must be determined and fixed, whether it is from inside or outside. If the damage is structural, then the source of the problem must be identified and a structural solution to the problem must be found. That can be done by either a site modification of the panels or replacement of the panels, depending on the extent of the damage. In the event that panels are damaged, the manufacturer and installer of the panels should be notified. There are SIPA members who can act as a consultant to assess the damage and recommend repair or replacement strategies.

Are SIPs susceptible to insects?

Although termites do not feed on the foam panel cores, there have been instances where panel cores have been hollowed out by these insects and used as a nesting ground. To prevent this, many manufacturers offer SIPs with borate-treated foam. Termites may also be deterred through the use of a specially designed steel mesh. Both these treatments are highly effective, but they are not a substitute for careful termite prevention and maintenance, as with any other wood structure.

Are SIPs susceptible to mold and mildew?

An airtight SIP building envelope forms the basis of a successful mold control strategy. The extremely low levels of air infiltration in SIP buildings allow for incoming air to be provided in controlled amounts by air handling equipment. Proper dehumidification of incoming air following ASHRAE standards will create an environment where mold physically cannot grow.

In addition to creating an airtight structure, SIPs are solid and free of any cavities in the wall where moisture can condense and cause unseen mold growth.

Learn More about SIPs

Where can I learn more about SIPs?

There are a number of resources on structural insulated panels:

Builders can participate in both online and hands-on SIP installation courses through the SIPA Registered Builder Program.

SIPA offers an AIA Continuing Education course for design professionals.

What is the learning curve for SIP installation?

For construction professionals competent in standard wood framing techniques, the task of learning SIPs is not difficult. The SIPA Registered Builder program offers both online and onsite training courses covering everything builders need to know about SIP installation.

Many SIP manufacturers and dealers/distributors also offer onsite technical assistance for builders that are new to SIP construction.

Where can I find information to design and engineer a SIP building?

Contact us today for more info!