At Foam Laminates of Vermont, we use EPS (expanded polystyrene) foam cores to give you a product that will serve your needs for years to come. We also recognize the need to produce a product that is safe for the environment. Other insulation products such as polyurethane use chlorofluorocarbons (CFC’s) in the manufacturing process. These CFC’s are light gases that escape from the polyurethane. This outgassing reduces the R-value of the product and contributes to the depletion of the earth’s ozone layer. EPS, on the other hand, uses captured air from its thermal properties. For you, this means a product that will maintain its R-value for the life of the home, while giving you peace of mind, knowing that you have not contributed to harmful ozone depletion.

Renewable Natural Resources

Foam Laminates of Vermont uses OSB as the facings for our SIPs because they are environmentally friendly. These OSB SIPs are environmentally friendly because they typically contain softwoods such as poplar and aspen, which are fast-growing trees harvested on a tree farm when they are young. This is important in a green society because the emphasis is on newer and faster-producing trees which protect the old-growth forests. As a result of this protection towards old-growth hardwoods, OSB is generally referred to as a sustainable and renewable natural resource. All OSB off-gassing occurs at the OSB mill.

Greater Energy Savings

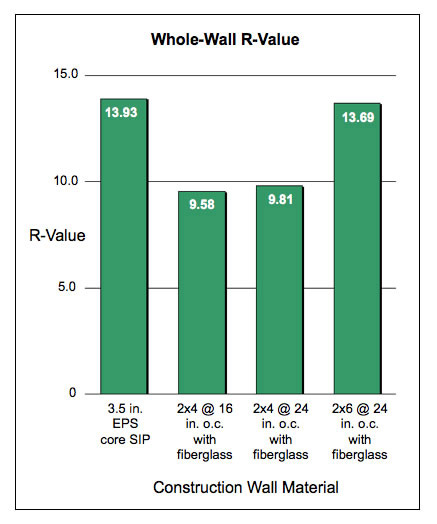

Perhaps the greatest reason of all why SIPs are exploding into the marketplace is because of their superb energy efficiency and superior thermal performance. An analysis conducted by the Oak Ridge National Laboratory (ORNL) compared the average insulation value (whole-wall R-value) between a SIP wall and some other traditional construction wall sections. Their study determined that a 3.5 in. EPS core SIP outperformed its counterparts in thermal efficiency. Their results are tabulated in the graph above.

One of the major concerns for any homeowner is the inability to control rising energy costs. Recently, there have been spikes in propane, heating oil, electricity, and even the labor associated with felling, splitting, and drying wood for home heating. However, SIPs offer a window of hope; SIPs are virtually airtight due to the nature of their fabrication and installation. As a result, the occupants have much more control over their interior environment.

More Resource Efficient

SIP panels are extremely resource-efficient and as such support the green building industry. For starters, there is little doubt that there is much less wood required to construct a SIP shell than in a conventional stick-frame. The OSB that is used as the facings in a SIP panel comes from younger growing farm trees, which are generally regarded as a renewable and sustainable resource. These trees such as aspen and spruce are harvested from fast-growing crop forests and thus no old-growth timber is used. The table shown below depicts the typical amount of wood used in a stud framed wall compared to a SIP wall.

Comparison of Wood Products Used

In a Framed Wall vs. a SIP Wall

| Wall Configuration | Whole-wall R-value | Dimensional Lumber (in board feet) | OSB (in board feet) | Total Board Feet |

|---|---|---|---|---|

| 8-ft. X 8 ft. 2X6 Wall | 13.69 | 105 | 32 | 137 |

| 8-ft. X 8 ft. 4 1/2-in. SIP Wall with EPS Core | 13.93 | 20 | 64 | 84 |

Non-Toxic Chemicals

Foam Laminates of Vermont uses EPS foam as the insulating agent in our Structural insulated panels (SIPs) because they do not contain any Formaldehyde or C.F.C’s: the disastrous compound responsible for ozone layer depletion.

Reduced Emissions

The Environmental Protection Agency (EPA) estimates that the average U.S. home releases 22,000 lbs of carbon dioxide (CO2) into the atmosphere each year. This is twice the amount of the average vehicle. By reducing the amount of energy used for heating and cooling, Structural Insulated Panels (SIPs) can significantly reduce emissions produced by our homes and commercial buildings.

Indoor Air Quality

In recent years, a growing body of scientific evidence suggests that the air inside the places we live and work can be more polluted than the air outdoors. This poses a serious health risk to occupants. Poor indoor air quality can lead to irritation of the eyes, nose, and throat. Furthermore, this can also increase susceptibility to headaches, viruses, and asthma-like symptoms.

Energy Efficiency

Structural Insulated Panels (SIPs) have a high R-Value foam core without any thermal bridging studs or areas of potential compression or voids in the insulation. SIP homes also have extremely low levels of air infiltration because there are fewer gaps to seal. When combined with other high efficiency energy systems, SIP homes commonly demonstrate 50%-70% savings over the Model Energy Code (MEC).

Foam Laminates Building System Checklist

- Easy Installation

- Factory Controlled Quality

- Greater Energy Efficiency

- Comfortable Living Environment

- Reduced Mortgage Payments

- Lower Utility Bills

- Faster Construction Time